PCB Design & Simulation

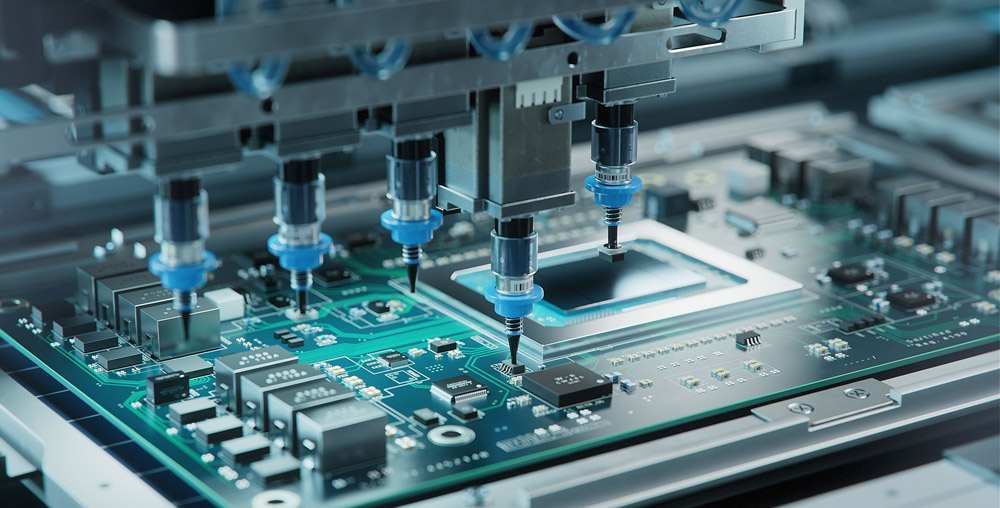

High-speed, RF, rigid-flex, and dense multilayer layout using Altium and KiCad with full DFM checks.

Turnkey PCB Design • Hardware • Firmware • 3D

Greentrace Studio partners with ambitious hardware teams for rapid schematics, dense PCB layout, firmware bring-up, reverse engineering, and enclosure modelling when documentation is thin. We stay onboard until your first article survives QA.

Custom PCB layouts delivered

Average concept-to-layout handoff

QA aligned documentation

RF, thermal, environmental validation

Teams we accelerate

Greentrace Studio adapts compliance, sustainability goals, and documentation rigor to match each industry vertical.

Capabilities

Work with a single team that can capture requirements, implement hardware, model enclosures, and prepare production-ready packages.

High-speed, RF, rigid-flex, and dense multilayer layout using Altium and KiCad with full DFM checks.

System architecture, component selection, power budgeting, bring-up, and validation documentation.

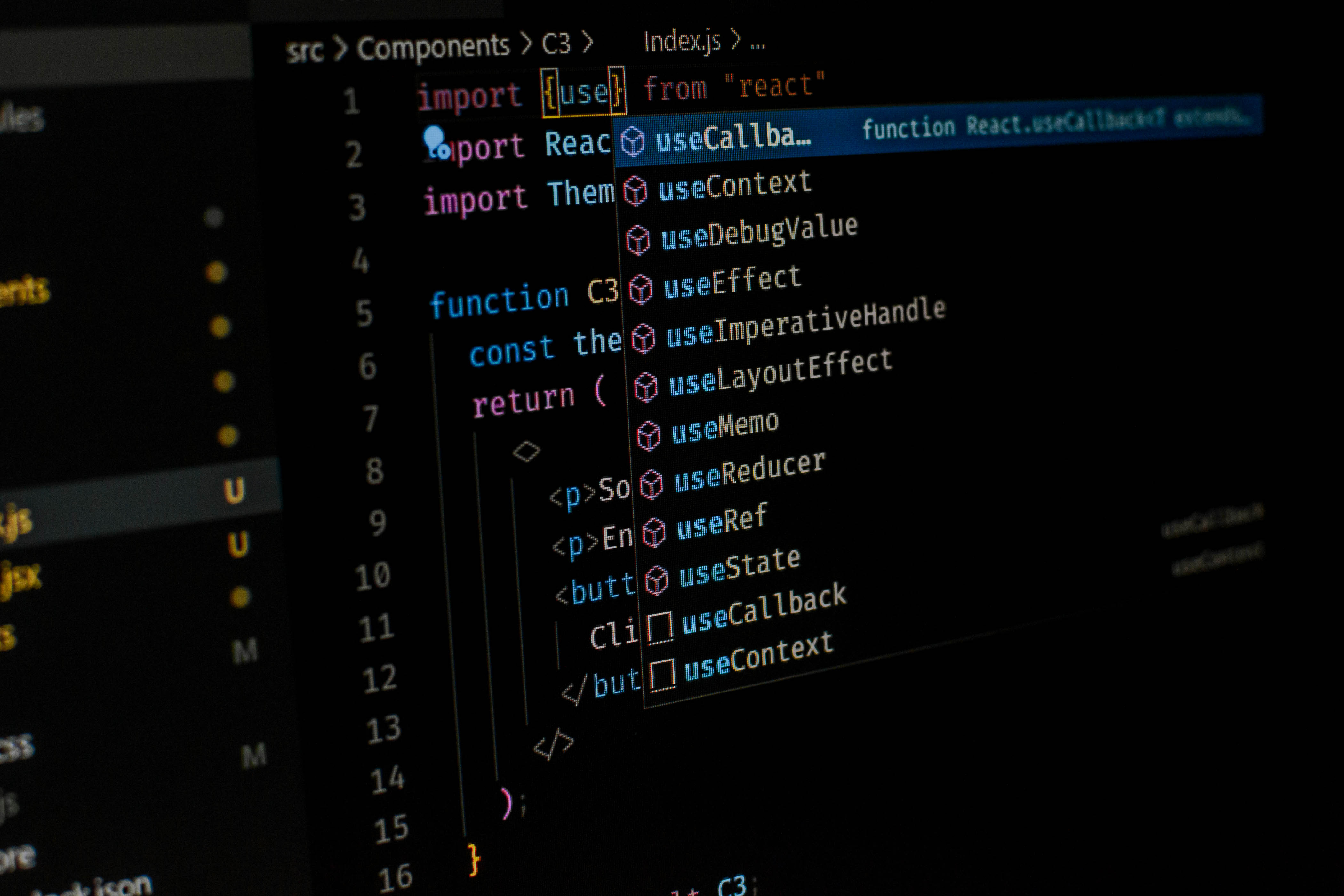

Bare-metal and RTOS development for STM32, ESP32, Nordic, Microchip, and custom bootloaders.

Mechanical integration, thermal simulation, and 3D printable models that align with PCB keep-outs.

Legacy board recreation, documentation rebuilds, and BOM modernization for unsupported hardware.

Gerber, ODB++, assembly drawings, test fixtures, and vendor coordination until first article approval.

Why teams choose us

We combine collaborative reporting with lab-grade validation so you know exactly how your hardware behaves before production.

6 GHz VNA, multi-channel thermal imaging, and automated load banks capture evidence for every design decision.

Time-stamped PDFs, Gerber snapshots, and firmware diffs land in your inbox with action items and blockers.

Encrypted vaults for NDAs, segregated build servers, and redacted doc sets for vendors keep IP safe.

Workflow

We translate requirements into an actionable specification with schedules, deliverables, and budgets.

Iterative design reviews plus simulation snapshots keep stakeholders aligned.

Firmware sprints, bring-up logs, and validation testing ensure every board boots flawlessly.

Manufacturing files, test plans, and on-call support until the first batch passes QA.

Industries Served

We adapt compliance, BOM, and thermal strategies per industry, from harsh industrial automation to wearable consumer tech.

Lab snapshots

Signal integrity benches, accelerated life testing rigs, and firmware pods stay hot so your sprint never waits on lab time.

6 GHz VNA, TDR probes, and automated eye-diagram capture keep high-speed channels honest.

Includes fixture fabrication + SI reporting.Thermal shock, humidity, and 3 m drop rigs accelerate field failures before customers ever see them.

Live dashboards share pass/fail evidence.Dedicated bring-up bench with logic analysis, RF sniffing, and automated regression harnesses.

Perfect for OTA, BLE, and IoT stacks.Featured Samples

HDI routing, impedance control, stack-up modelling, and automated DFM with Gerber snapshots.

PCB • DFM

Driver bring-up, secure boot, regression benches, and OTA orchestration with live telemetry.

Firmware • Automation

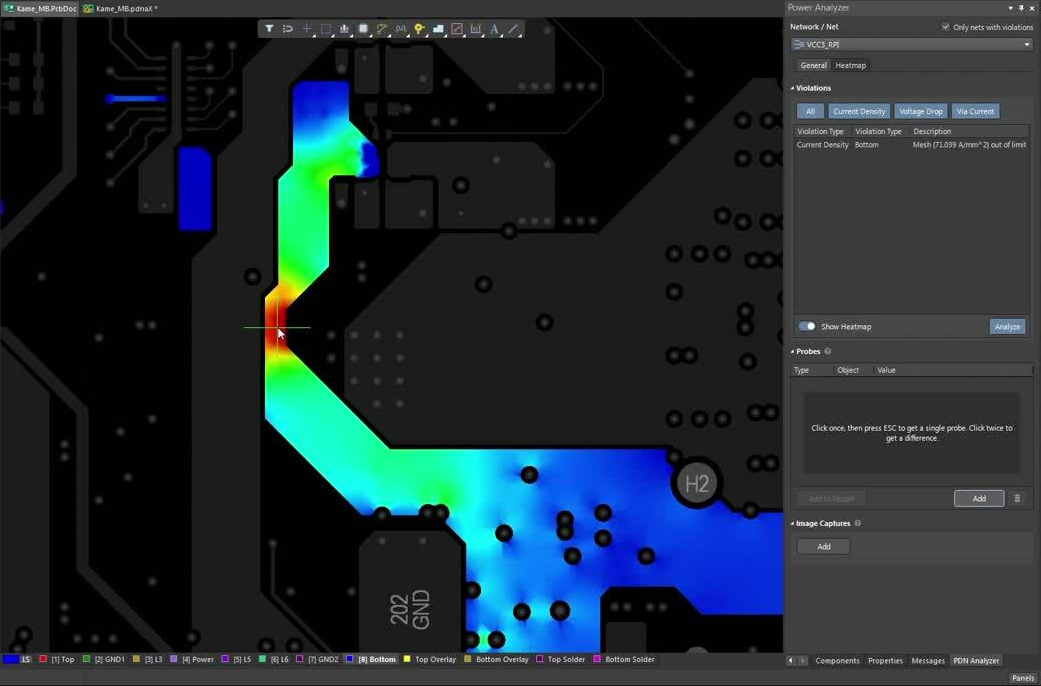

Stack-up solvers, signal-integrity eye analysis, power-integrity droop checks, and electro-thermal sweeps feed executive-ready validation dossiers.

PCB • Simulation

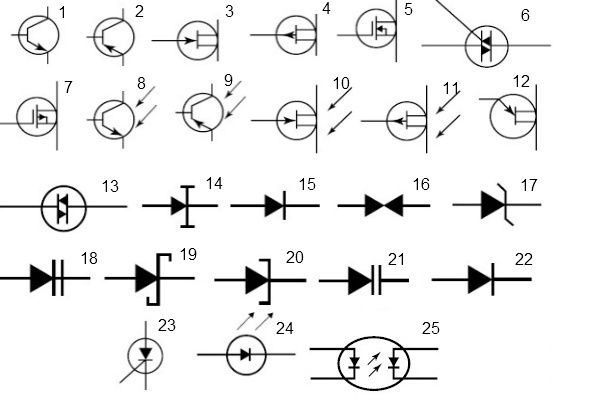

Authoritative libraries with IPC-compliant naming, metadata, and real-time sync into Altium/KiCad.

Symbols • Governance

IPC-7351 footprints, 3D step alignment, assembly notes, and rotation metadata for CM import.

Footprints • QA

Flex-rigid PCB, BLE telemetry, low-noise analog front-end, and body-safe coatings.

PCB • Firmware

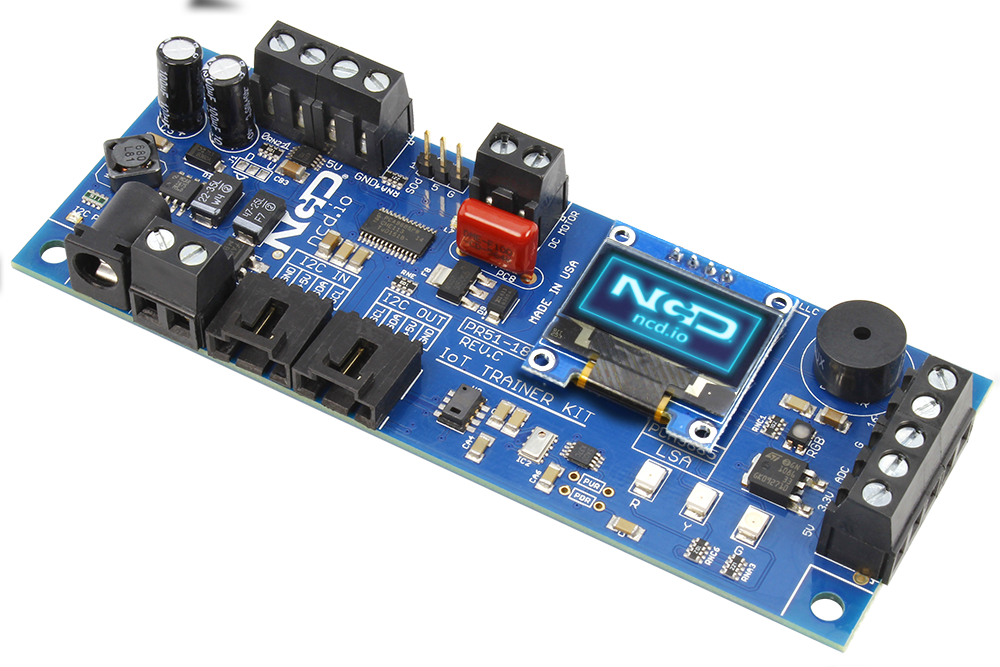

Quad-core MCU, isolated IO, reverse-engineered fieldbus, and hardened OTA stack.

IoT • Reverse engineering

Snap-fit housings, integrated heat pipes, printable prototypes, and CMF-ready documentation.

3D models • Thermal

Netlist recreation, protocol sniffing, BOM modernization, and re-spin ready schematics.

Reverse • SustainingNeed a quote?

We reply with milestones, sustainability levers, and transparent pricing within one business day. Attach NDAs or BOM snapshots right inside the popup uploader.